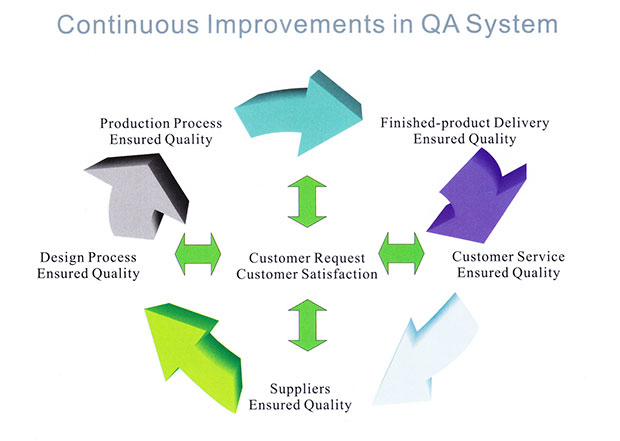

General Principles

We set up a standard QC system by Quality Manual, Process Documentation, Operational Guidebook (included Management, Technology, Equipment, Product.), QC Record these four documents based on rules of ISO9001. The QC system was examined, corrected constantly to make it perfect, to ensure our products are qualified.

Quality Policy

We make high quality LCD products to meet the various demands of users

We will concentrate the style of our company and experience of our staff on our products.

We will keep on studying new problems, researching new technology, adopting new materials, improving our quality system for both our products and service. We will have every member of our company trained with necessary knowledge and technics.

Running Guarantee for QC system

SGS auditing our QC system once every half a year Our inner ISO9001 auditing group auditing our QC system once every half a year. General Manager takes charge of auditing on management status. Staff of our company should be concerned with《Correction and Prevention Procedure》.

Quality Guarantee

Apply advanced equipment, technology, and good materials which are mainly imported from Japan and Germany. All the materials must be examined before they enter our factory.

The production is operated by well trained and skillful workers.

We have a strict system for quality controlling, which is supervised by our specialty QC department. It's a dedicated, executive and professional team. There are 22 examine spots, 5 quality check spots in the key working procedure. A new product must pass through auditing twice, and must be approved by customer before we can start mass production.

Environment Reliability test: High temp Storage, Low temp storage, High temp and high humidity test, Temp cycles test, Vibration shock test. F. Product Inspection Standard: Shenzhen Enterprise product standard

日本語

日本語 English

English